BÖHLER K190 MICROCLEAN

BÖHLER K190 MICROCLEAN is a 12% ledeburitic chromium steel manufactured using powder metallurgy. This material has the highest alloy content of the group of 12% ledeburitic chromium steels. Due to its high vanadium content, BÖHLER K190 MICROCLEAN has a significantly better resistance to abrasive wear than the tool steels 1.2080, 1.2601, 1.2436 and 1.2379. At the same time, the powder metallurgical manufacturing process creates a uniform matrix with finely distributed primary carbides, which among other things contributes to the good toughness of the material. BÖHLER K190 MICROCLEAN is used in situations where tool steels like 1.2379 are insufficient in terms of wear resistance.

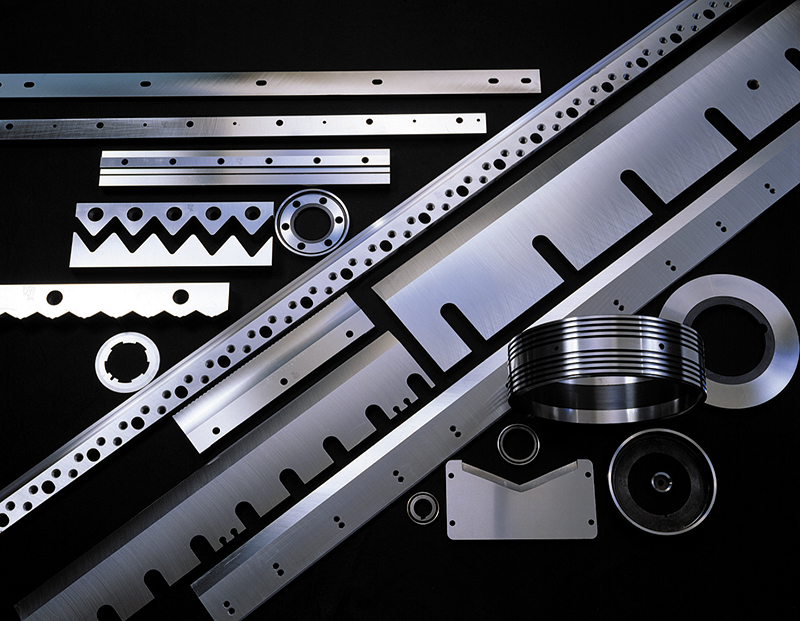

Available Product Shapes

Long Products: Presented data refer exclusivly to long products. Please observe the detailed explanations at the end of the data sheet (pdf).

Melting Route

Powder metallurgy

Property Features

- Wear Resistance: high

- Compressive strength: high

- Toughness & Ductility: high

- Dimensional stability: very high

Technical Specifications

Material Numbers

- SEL

- ~1.2380

- EN

- ~ X230CrVMo13 4

Chemical Composition

* Chemical Composition (Average %)

- C

- 2.30

- Si

- 0.60

- Mn

- 0.30

- Cr

- 12.50

- Mo

- 1.10

- V

- 4.00