-

Tooling

Aerospace & Power Industry

Oil & Gas, CPI & Renewables

Industrials

The Best in the World

voestalpine High Performance Metals USA

Materials forToolingAerospace & Power IndustryOil & Gas, CPI & RenewablesIndustrialsThe Best in the World

For the Worlds Top Performers

For generations, the name BÖHLER has been synonymous worldwide with special steel of the highest quality. Our customers are leading companies in future-oriented industrial sectors and highly innovative specialists who push the boundaries of what is possible with their solutions. The new stainless steel plant secures this leading position for future generations.

The new stainless steel plant in Kapfenberg

With the world’s most modern special steel plant opening in 2023, we are setting a technological milestone in the production of pioneering high-performance steels for the international aviation, automotive and oil gas industries. The high degree of digitalization, the most efficient use of energy and the highest environmental standards make the plant unique in this respect too.

Our products at a glance

High Speed Steels

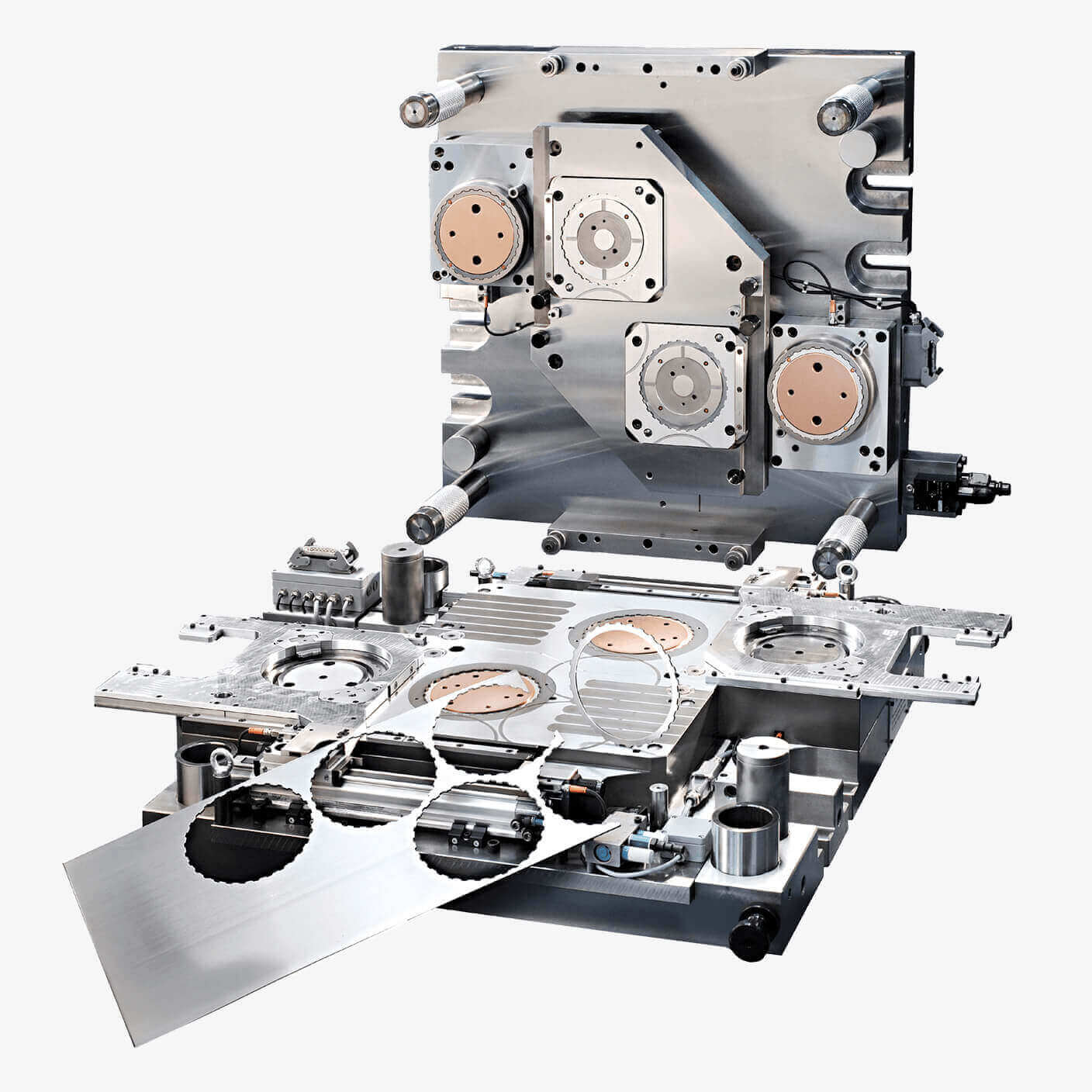

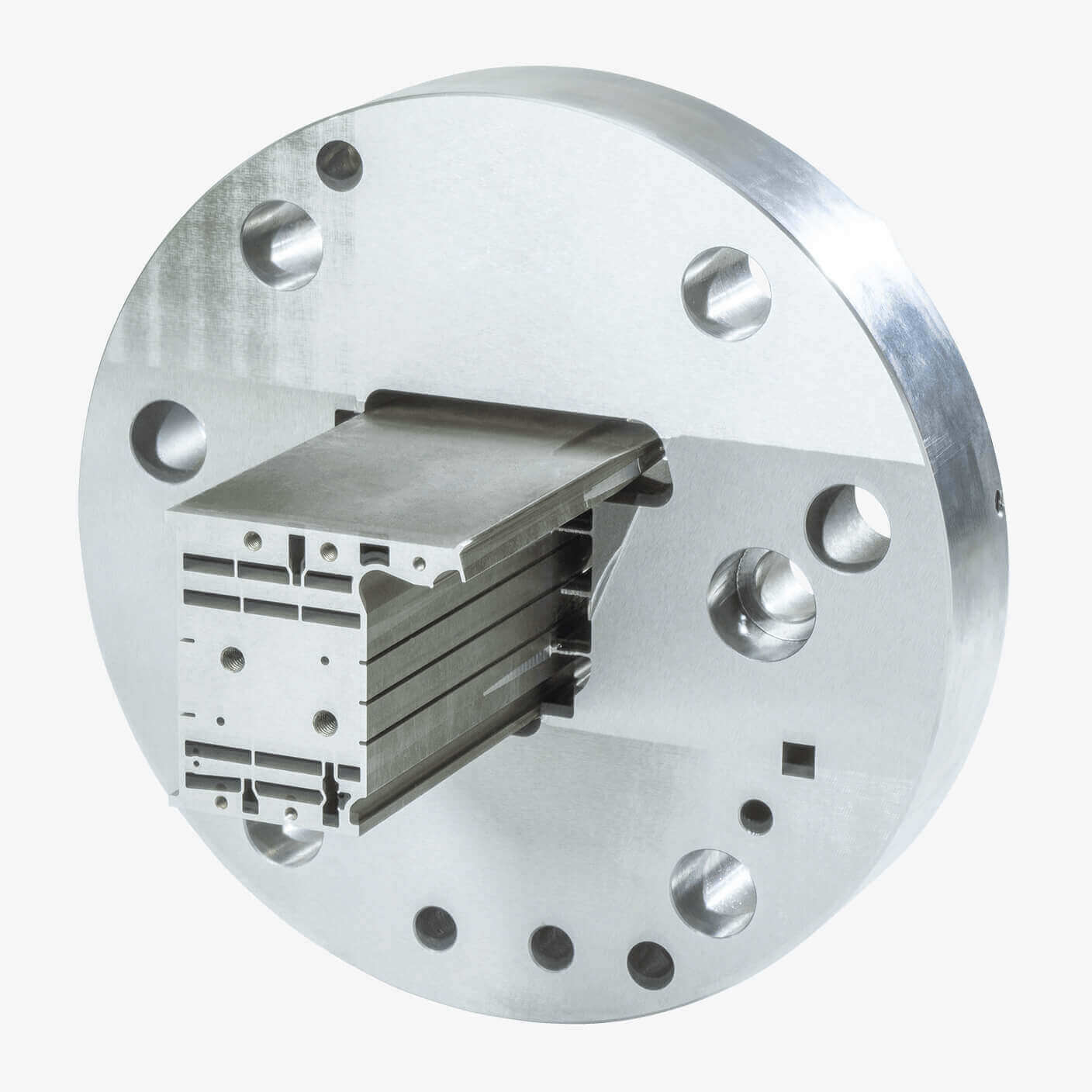

Cold Work Tool Steels

Hot Work Tool Steels

Plastic Mold Steels

Ni-based Alloys

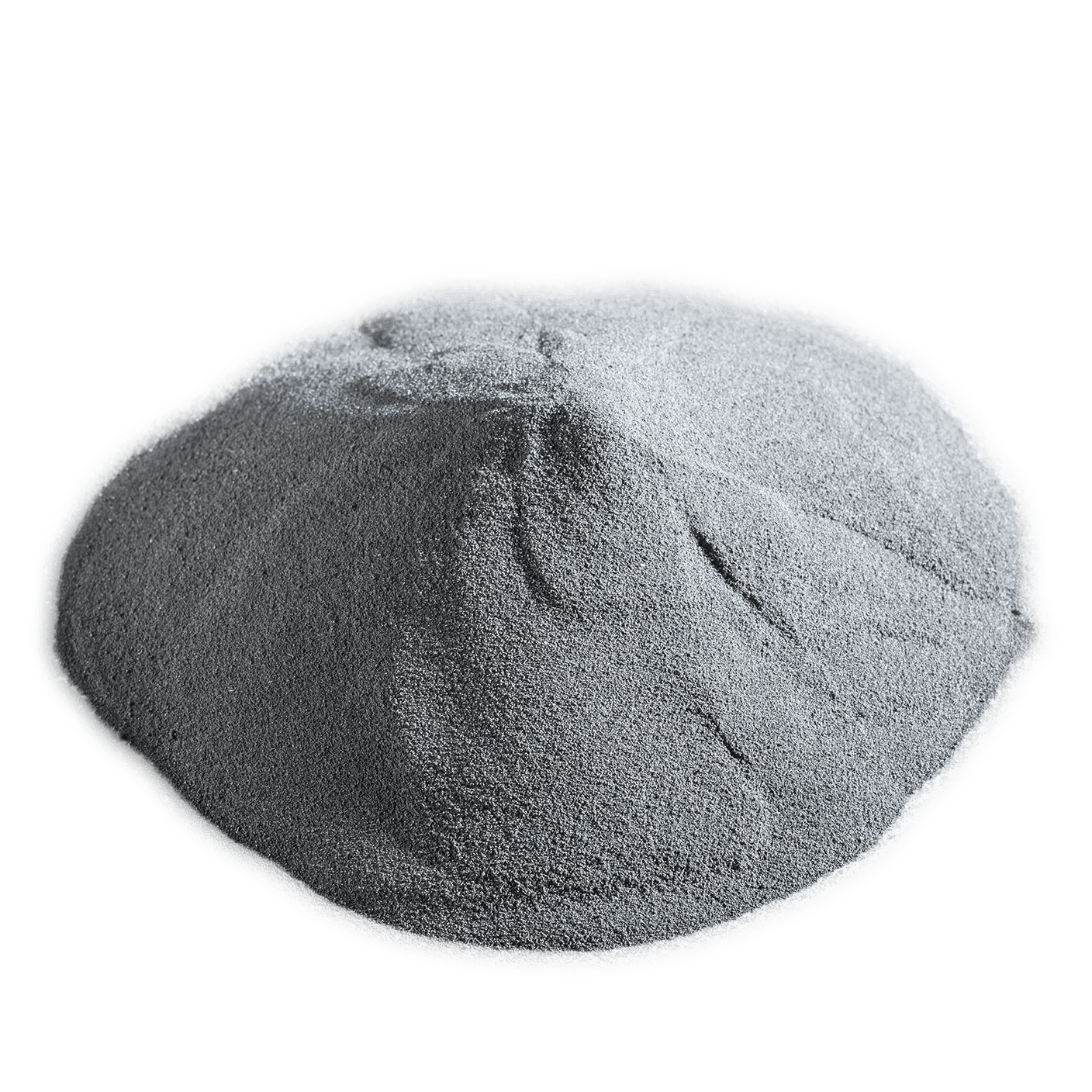

Additive Manufacturing Powder

-

Cutting Tools

Cutting processes, e.g. drilling, milling, threading or broaching, require tools made from selected high-speed steels. BÖHLER high-speed steels optimally combine the required properties such as high edge retention, hot hardness and toughness. For our customers, this means reliable and reproducible production processes, long tool life and lower set-up costs. -

Aerospace

The aviation industry demands reliable materials for airframes, engines and landing gears. BÖHLER produces and supplies steels and alloys according to given specifications and standards, in the desired composition and dimensions with the desired properties. Every single production and testing step is in our hands and ensures quality at the highest level -

Hot Work

BÖHLER hot-work tool steels are mainly used in highly stressed forging and die-casting tools and, due to their good combination of properties, also in cold work and plastics processing. The main focus is on offering customized material solutions with high-quality, remelted steels. -

Engineering

BÖHLER offers its customers tailor-made material solutions in the fields of medical technology, luxury watches and the electronics industry. Industry standards at the highest quality level and innovative products for special challenges are our specialty, e. g. low-Ni steels for watches and medical technology. -

Oil & Gas / CPI

Safety-related and economic challenges in these segments demand a wide range of properties from the materials used. The product portfolio includes proven, highly corrosion-resistant steels and alloys of high quality. Voestalpine Böhler Edelstahl is a fully integrated manufacturer of nickel and steel alloys for these demanding industries. -

Automotive

The automotive product portfolio includes soft magnetic materials, high-performance case-hardening steels as well as High Speed and hot-work tool steels. BÖHLER produces and supplies highly functional materials, primarily for the highly stressed powertrain area and for injection components under high quality and product safety standards.